Name: Ivy Yang

Tel: +86 0731 22160466

Fax: +86 0731 22160196

Mobile: wechat/whatsup ID +86 18107334899

E-mail: sales@upcarbide.com

E-mail: ivy@upcarbide.com

Add: No.849,Hongqi North Road,ShiFeng District,Zhuzhou City,Hunan Province,China. post code 412000

Skype: ivyyang316

MSN: yangjuan316@hotmail.com

QQ:

2498362811

|

Product name : 65HRC Φ140mm G20 tungsten steel polished ball

Product No. : Φ140mm

|

| Details: | ||||||||||||||||||||

65HRC Φ140mm G20 tungsten steel polished ball

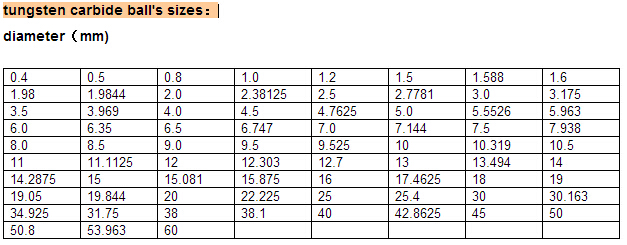

65HRC Φ140mm G20 tungsten steel polished ball tungsten carbide pellet is high hardness, wear resistance, corrosion resistance, resistance to bending, the use of harsh, can replace all the steel ball products. 1. all kinds of sizes,the diameter from 0.3~60mm. We can also provide non-standard alloy ball size, size and precision for production according to customer's requirements. tungsten carbide pellet's grades:

tungsten carbide pellet's common grades and advantages: grades:YG6,YG8,YG6X,YG13,YN6,YN9,YN12,YT5 and YT15. tungsten carbide pellet's applications: Carbide ball scope is very broad, such as: precision punching drawing, precision bearings, instruments, meters, pen, tungsten carbide pellet's processes: Pulverizing to formula→ according to the requirements of USES→ the wet and dry mix → crushing -→and sieving |

| Related Products : |

tungsten carbide needle

tungsten carbide needle

unground ball

unground ball